- HOME

- English

- Business Introduction

- ODM, plastic molding & assembly

ODM, plastic molding & assembly

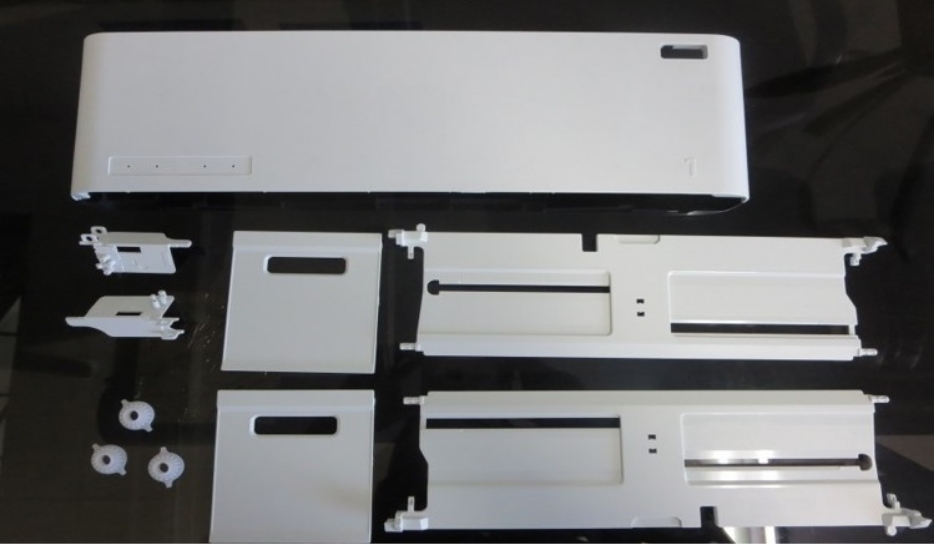

Plastic molding & ASSY for OEM/ ODM products

We offer a full range of ODM/OEM production services, from tooling design & fabrication for plastic to molding, painting, and assembly.

We are particularly experienced in the production of parts for OA, home appliances, in-vehicle parts, and audio. And some of our products are also available for packaging and shipping to mass retailers after assembly and commercialization.

Business partner

Panasonic

MITSUBISHI HEAVY INDUSTRIES THERMAL SYSTEMS

SUN-S

MITSUBA

NIDEC

KOSS

CANON

BROTHER

Sumitomo Wiring

Systems

MORIROKU

TECHNOLOGY

BENESSE

Ryohin Keikaku

MTG

HOSIDEN

Furutaka

Electronics

※in no particular order

Main Products (ODM/OEM)

OA equipment

We manufacture plastic molded parts of copier chassis, appearance parts, toner cartridges, etc., as well as gears and insert molding parts with shafts for mechanical parts.

Besides OA, we also manufacture plastic bands and bezels for watches.

Audio products

We manufacture plastics parts and components used in speakers, headphones, and earphones, as well as internal mechanical parts for CD players etc.

Our own development team can provide support from product planning to mass production.

Home Appliances/ Medical equipment

We produce plastic parts for the appearance of humidifiers, air purifiers, remote controls of water-heating system, cooling-fan units for conditioning wears, sewing machines, air conditioners, etc.

We can paint and print on the appearance parts for medical and beauty equipment, health appliances, humidifiers, etc., and can also produce plastic parts for mechanisms of the products.

Related Products of Automobile and Motercycle

We design waterproof housings for drive recorders installed in automobiles and motorcycles, as well as communication systems and image transmission systems.

We conduct housing endurance tests and plug insertion/removal tests to enhance vibration endurance reliability, and strive to provide highly reliable parts and materials.

Work Flow of OEM/ ODM

We can introduce the flow from inquiry to design/development, mass production, and delivery.

First, please contact us through the inquiry form in our HP or by phone.

Our salesman will contact you shortly.

Click here for the inquiry form

Interviews, Suggestions and Quotations

Support from early stages such as planning proposals, technical advice and consulting. Based on the content of the interviews, we will conduct market research and analysis and study products concept.

We carefully listen to customers' conditions of the scheme, product content, shape, specifications, delivery, price, quantity, etc. Once customers are satisfied with our suggested specifications, we will provide quotation.

Product Design and Materials determination

We provide reliable quality design services based on our extensive know-how cultivated through product development experience.

Our development team, manufacturing team, and QA team work closely together to help realize production without defects in terms of customers' requirements, practicality, and quality.

Prototyping (evaluation machine) and test evaluation

We conduct various tests on the completed evaluation machine after building it according to the product specifications.

Thorough inspections will be carried out to ensure that prototype products are completed as designed.

We can also provide our reliable and effective testing additionally to the functional and performance testing for the prototypes.

Mass-production

We handle everything from prototype production to mass production, modification, and sales.

As well as arranging assembly, packaging and shipping of products of various sizes. We provide consultation on modification of developed products and support quality control.

Click here for inquiries about ODM, plastic molding & assembly business

Please contact us using the inquiry form below.

FAQ

Can you provide specifications when requesting OEM?

By using various technologies, it is possible for us to determine the specifications while the customer reviews our proposal.

How competitive are manufacturing costs in China?

It is true that labor costs in China are getting higher as compared with the past. We have established close partnerships with suppliers that have a competitive edge in terms of quality, cost, and delivery time, and have overcome tough competition in the huge China market, and we will spare no effort to bring our products closer to our customers' QCD requirements.

What is the difference between OEM and ODM?

OEM: We manufacture products by customers' specifications, quality standards, etc. ODM: We design and develop products while listening to customers' requests and manufacture and deliver finished products after customers' approval for the specifications.

Click here for other companies information

~Inquiries by phone~

Nara Office : +81-743-54-7780

Mon.-Fri. 9:00am – 18:00pm.